EPC-M Group Company Profile

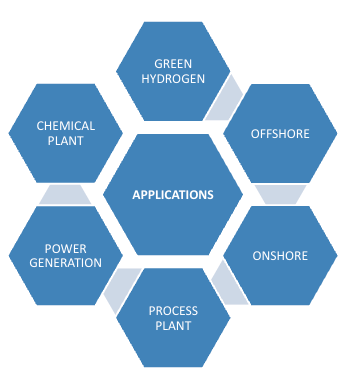

EPC-M Group is established with Waterfront Fabrication Yard Facilities, professional management and Strong Project Management Teams to execute O&G Process Module Projects profitably, with HSE Target of Zero Lost Time Injury (LTI), good quality control and on-time delivery to meet customers’ requirements for the module EPC companies.

With the strong support from the network of the FPSO Industry and good relationships with Customers, Fabrication Yards, Sub-Vendors, Contractors, Equipment Specialists, Technology Holders, Specialist Craftsmen, Logistics and Supply Chain, we are set to provide Engineering, Procurement and Construction Management Services.

As a natural progression, in the Decarbonization Transition Journey, we are also Developing Renewables, Green Hydrogen and Green Ammonia Projects With Local Partners.

In Partnership with International Green Hydrogen Technology Companies & Financiers, we support the projects through Feasibility Studies to accelerate the Project Financing, Technology Selection and Development process.

With a holistic approach incorporating the whole Eco system of Green Hydrogen including:

- Renewables, Green Hydrogen Production, Storage, Various shipping options using different Green Hydrogen carriers.

- Micro-grid and other applications

- Blending Green Hydrogen to existing Gas Fired Power Plants.

For more information, download our high-resolution brochures here:

We have the Core Competencies in O&G Process Module Fabrication with Access to Waterfront Fabrication Yard facilities including teams for:

- Health, Safety, Environment (HSE)

- QA / QC

- Process Design

- Detailed Engineering

- Shop Drawings

- Construction

- Project Management

- Procurement

- Logistics

- Business Support

HSE Policy

EPC-M Group places great importance on and takes responsibility for the Health and Safety of its employees.

We act in accordance with the applicable statutory and international standards regarding environmental protection, and seek to conduct fabrication of oil and gas equipment in manners that avoid harm, injuries and accidents to our employees and the Environment.

- Comply with relevant authorities, standards and statutory requirements for HSE

- Control hazards and take the best possible precautionary measures against accidents

- Provide training and ensure that employees are educated in health and safety issues

- Use an occupational Health, Safety & Environmental management system

- Minimise environmental pollution and make continuous improvements in environmental protection

- Ensure that employees are suitably trained, adequately instructed and supervised in their duties, in the safe use of equipment and materials and in the correct disposal of scheduled waste

It is EPC-M Group’s requirement that every employee and personnel working with us appreciates and complies with our HSE policy.

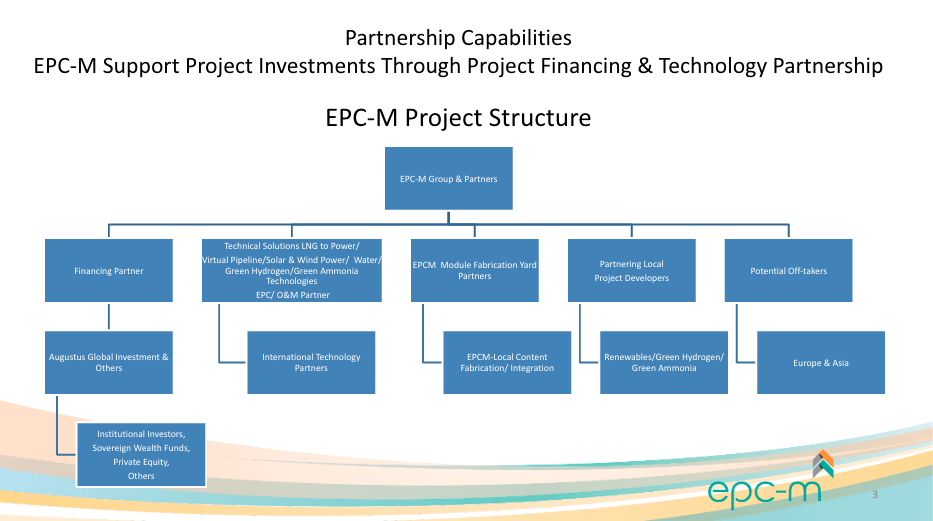

Partnership Capabilities

Key Success Factors

- HSE Target-Zero Loss Time Injury (LTI)

- Having High Health / Safety / Environment Awareness

- Accident Prevention Culture

- Honesty

- Integrity

- Meeting Quality Requirements

- Achieving On-Time Delivery

- Achieving Cost Control and Profitability Targets

- Prevention Of Inefficiencies & Profit Leakages § Management With The Heart, Not Just The Head

- Motivating members to giving the best efforts work culture

- Appreciation Of Efforts & Contributions work culture

- Having A Sense Of Achievement among Team Members

- Customer Satisfaction

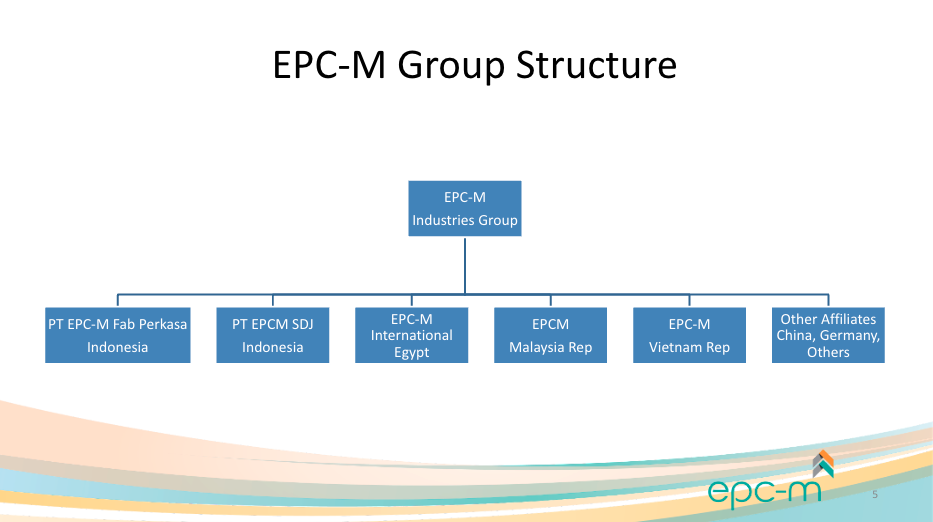

EPC-M Group Structure

Your Preferred Fabrication Partner

EPC-M Group provides EPC-Management Services and access to Waterfront Fabrication Yards For O&G Process Module Businesses, equipping you with:

- Your Remote Fabrication Yard

- Your Remote Fabrication Team

- Fabrication of Process Equipment Packages

- Module Construction

- Fabrication of Other Related O&G Products

Our Fabrication Yards

Use of fabrication yards with waterfront access

Specialist Skills

- Multi-Discipline Fabrication Capability (Structural, Piping, HVAC, F&G Systems, Electrical, Instrumentation etc)

- Capability to Fabricate Different Materials (CS, SS, Duplex, GRE 7000M etc)

- Combining Engineering, Project Management And Procurement To Achieve Quick Delivery

- Recovering Lead Time “eaten” by Engineering Changes via Night Shift

- Flexible Engineering Capability To Accommodate Drastic Changes Made By Client At The Last Minute

- Meeting International Codes (especially electrical testing)

Engineering Design Software

Process / Safety Design Software: HYSYS / FlareNet / HTRI / HTFS / Pipenet

Piping / 3D Modeling Design Software: CAESAR II / PDMS / PDS/NAVISWORKS / CLASH MANAGER / AUTOPLANT

Structural Design Software: SACS / STAAD / NASTRAN

Electrical Design Software: ETAP / Chimelite

Instrumentation Design Software: Intools / Instrucal

Mechanical Design Software: PVElite / CADVent / Carrier

Project Control Design Software: PrimaVera

EPC-M develops the following in-house capabilities:

- Engineering

- Admin & Finance

- Detailed Engineering

- Procurement

- Process Evaluation

- Shop Drawing

- Construction

- Front End Engineering Design (FEED)

- Product Development

- Project Management

- Conceptual / Basic Engineering

- Core Competency